Step 3 |

|

The diabetes had really been beating me up and so three weeks before the beams came I signed up for

carpal tunnel surgery, fingers in my left hand were numb. About a week after the surgery, here comes the truck from Art Iron (Arco Steel), same fellow

that went off the driveway and lost the truck in the mud the spring before with over 75 tons of iron on

board. Kept him out of our driveway (neighbor boys had filled in the damage he did the time before) and

this time I remembered to wear gloves so that he wouldn't bloody me moving his clamps like the time before. And as I'm

standing there I think to myself, he's not stupid enough to try to roll a 200 lb beam that I'm holding onto, uugh.

Tough telling the surgeon how my thumb, the source of previous concern, was now a black and blue wonder. The pictures below illustrate the C-channel supports, the rope trick using stainless steel eyebolts to redirect the force, and the brush that has grown up as a result of hiding indoors all summer. One of the compelling reasons for pulling the plug during the month of August is that every year I have gotten into some toxin during that month that has landed me in the hospital 3 out of the last 4 years. Last year, I almost lost both arms and the hormone treatments needed to knock it down were undoubtedly the source of my current diabetes. So why tempt fate? Aluminum and stainless steel are pretty durable even if people are not! So far no sign of the Boogeyman, but we are keeping our eyes peeled. |

|

|

|

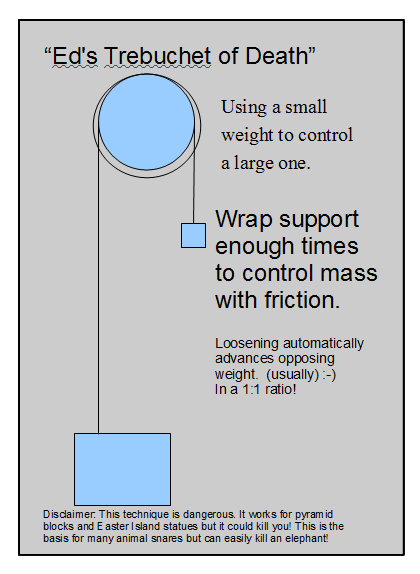

| I used an old Indian snare secret as a force amplifier to raise the 200 lb ridgepole with a 5 lb bucket of paint. Worked beautifully, I can now raise a 50 ton pyramid block or an Easter Island statue by myself and without breaking a sweat and without a pulley, cool!! Each time I levered the support beam for my greenhouse upward, the rope relaxed allowing the bucket to drop. After several minutes the beam was 10' up and the bucket was on the ground... Did I forget to mention that stored energy has a tendency to get loose, in this case about 2000 foot-pounds, hence my concern, a shotgun shell is about 60 foot-pounds as I remember. Good news, job is done! Understand this can become an odd sort of deadly trebuchet if you slip. Here is a program in Visual Basic to calculate the required counterweight (cw.zip). Well, you don't want to stand under the object, and work still equals force times distance. But yep, you can raise the dead with a 5 lb bucket! And I can reduce the power needed (energy per unit time-E/t) to near zero. This is especially important if you have a labrador retriever and are diabetic :-) |

Actual Data: Proving that I love to exaggerate and am afraid of dying (who knew?):

|

The first glazing appears. Can we get it caulked before winter sets in ???

|

|

|

|

|

|

|