Evaluation of Progress, Steps Needed to Finish: Part 13

"How do you eat an elephant?"

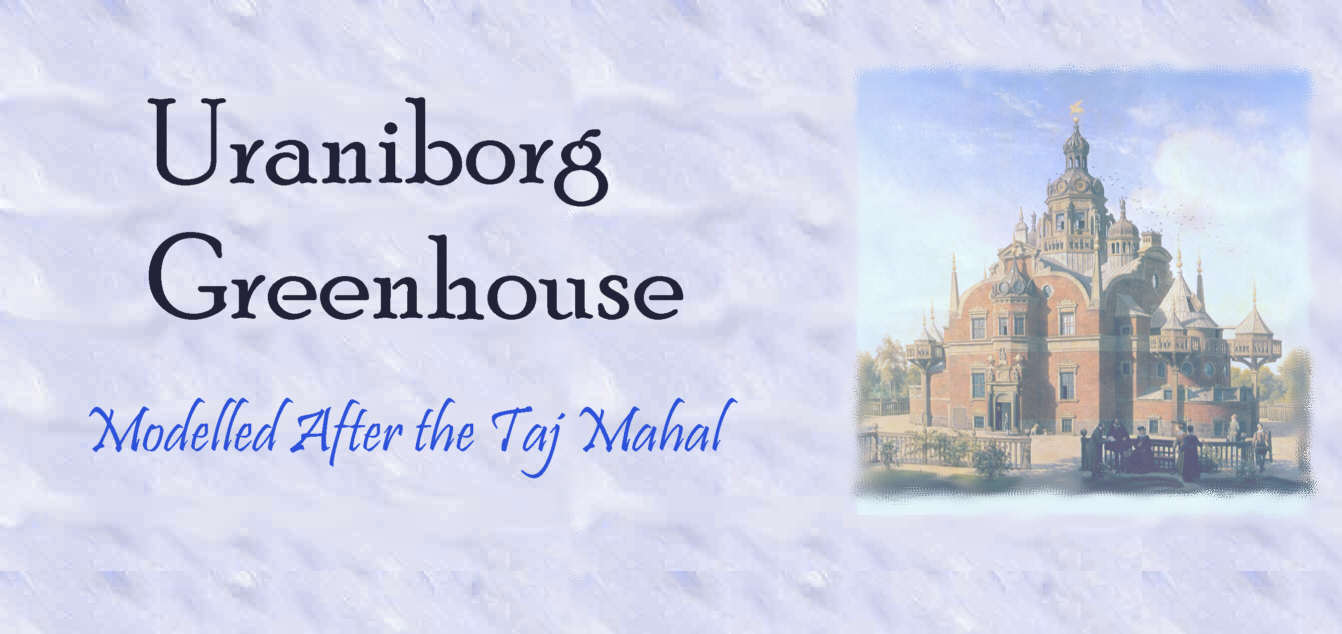

Green lettering---Green House, Yellow Lettering---Shop

Warning: Greenhouse door also doubles as time portal, be sure to close after use, see picture below...

| STEP | NEEDED FOR | EST/ACT TIME | EST/ACT COST | OK | DONE | |

| 1 | Install Electrical Power | Shop, constuction, GH | 2 weeks/1 week | $150/150 | X | July 2, 2009 |

| 2 | Install GH Door | Frame planning | 2 days/2 days+ | $150/150 | X | July 5,2009 |

| 3A | *Install Aluminum GH Frame lower | Glazing Support/frame | 2 wks /3month | $300/$700 | X | October 29, 2009 |

| 3B | ends | Ends + Vents | 3 wks | $500/$200 | X | June 2010 |

| 3C | upper | Roof | 1 wk/1 month | $300/$300 | August 2010 | |

| 4 | Install GH Glazing lower | Environmental Control | 1 wk | $500/infin. | X | August 2010 |

| Install GH Glazing upper | " " | ? | $500/$500 | -- | pending | |

| 5 | Install Water Supply | " " | 2 wks | $500/$1300bid | ||

| 6 | Panel saw and router jig | to install walls in shop | 1 day / 1 month! | $0/$80 | X | August 18, 2009 |

| 7 | Buy Table Saw and benches | projects and etc. | 1 day | $900 | ||

| 8 | Install shop walls/ceiling | not needed but nice | 3 wks | $0 | ||

| 8A | Install cabinets shop | tool storage, protect | ?? | ?? | ||

| 8B | Install cabinets lab | lab storage, protect | ?? | ?? | ||

| 9 | Install GH Lights | E. Controls | 1 wk | $200 | ||

| 10 | Install watering/heater controls | E. Controls | 1 wk | $200 | ||

| 11 | Ceiling insulation | to keep warm/cold | 1 day | ????$1000 | ||

| 12 | Install shop lights | Improve shop use .. | 2 hrs | $0-50 | X | July 8, 2009 |

| 13 | Install lab lights | Improve lab use .. | 2 hrs/2 hrs | $0/0 | X | July 7, 2009 |

| 14 | Install storage area lights | Darn good question | 2 hrs | $0-50 | X | July 12, 2009 |

| 15 | Shelving & benches frm OH | storage & workspace | 4-5 hrs | $0 | ||

| 16 | Desks from Old House (OH) | workspace | 3-5 hrs | $0 | ||

| 17 | Move bldg. mat. to barn | improve workspace | 3-5 hrs | $0 | July 2010 | |

| 18 | Pressure wash, clean floor | improve workspace | 3-5 hrs | 0-$150 |

To any former students, according to most industrial operations books the path to maximum productivity (thank you George Danzig) is to

do the easiest, shortest jobs first, exactly opposite what your mom told you to do. These tend to yield quickest, yield greatest profit, use up the

least materials, clear the most from your docket, make the most customers happy, clean up the shop floor, and pave the way to the more difficult

tasks by building capability. It may also be the reason I never get my greenhouse built. Could mom have been right after all??

#1 - Electricity  |

#2 - GH Door  |

#1 - REMC Gophers  |

#3-lower shell |

#6-panel saw |

|

July estimated cost to finish greenhouse is about $2000 and 7 weeks labor. Estimated cost to finish shop wais about $1700 and 4 weeks labor. The panel saw was a bad surprise. I broke out in hives about July 15 and still have the little buggers, I didn't realize how many measurements and screw sizes would hold up that project. I finally gave up on mounting pillow blocks at the base and bought a $4.50 piece of oak from Holmes lumber that I used to make two stop blocks. This means the saw won't fall out on my foot and it means the height is set where I want, not where it happened to show up. If I decide to document the panel saw you will see the pain involved, at least 20 different length and type of screws each purchased individually with a corresponding trip to town!! . Since it was on the critical path for both the greenhouse and shop, it really messed things up. Cut the uprights for the gh walls August 1. This meant: A. Chop saw cutting scheme for 2" aluminum works, yea. It also means I am now stuck with a wall height of 32-34 inches. If I chose 32, I can cut polycarbonate panes in 3 pieces but I lose light, I am drifting toward 34, hmm, thats a lot of patching but the appearance and light are better. Last entry August 18, 2009, panel saw marginally usable.

* See page 14 for thousand pound gorilla.